Situation

- Seal usually lies in the product, crystals agglomerate

Double seal AGSR for a vacuum paddle dryer

Situation

Challenge

Solution

Liquid crystals are complex organic compounds that are used, for example, in LCD flat screens (LCD = liquid crystal display). Electric voltage influences the orientation of the liquid crystals and the resulting light transmittance makes it possible to display the image. Even the smallest impurities in the production of liquid crystals affect their conductivity.

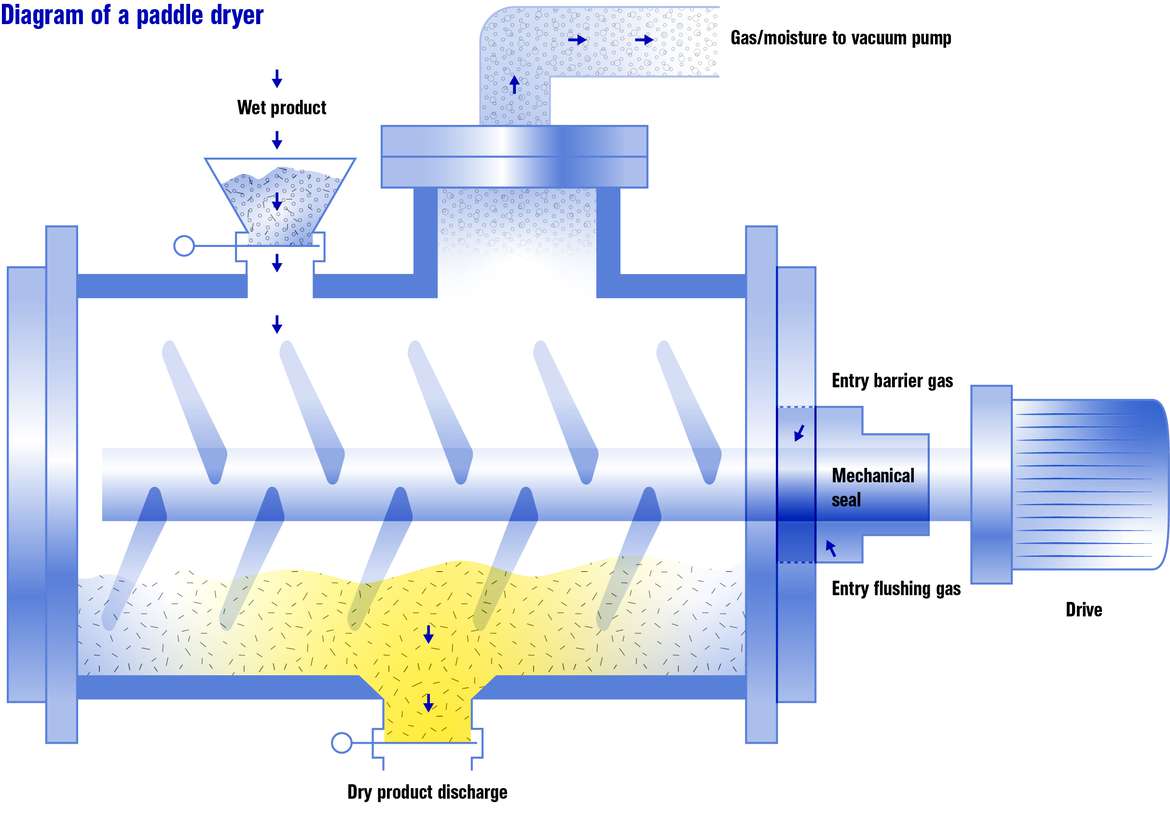

For many years, the Performance Materials business unit of Merck KGaA in Darmstadt/Germany has been using gas-lubricated mechanical seals of the AGSR series from EagleBurgmann that meet the demanding requirements for purity and cleanability in the production of liquid crystals. The seals are installed on the shafts of the side drives of several horizontal paddle dryers in which the crystals are dried.

The crystals are usually produced in a batch process and are present in various solvents such as toluene or methanol. Because of their physical properties, the crystals can easily accumulate on the seal. It is therefore essential to continuously flush the seals during operation. They must also be suitable for CIP processes (CIP = Cleaning In Place) in order to prevent subsequent batches from being contaminated by previous production and to ensure the function of the seal.

In horizontal paddle dryers such as those used at Merck, the seals are also usually to be found in the product. It is therefore necessary to reliably prevent contamination from the barrier medium used as well as abrasion from the sliding faces. A further requirement for the sealing system was compliance with Directive 94/9/EC (ATEX 95) or 2014/34/EU, which regulates the commissioning of machines in potentially explosive atmospheres.

The AGSR mechanical seal from EagleBurgmann is a gas-lubricated double seal. Since the seal faces run without contact, contamination through abrasion from the sliding faces is avoided from the outset. Specific design features of the seal, such as smooth surfaces in contact with the product and an open O-ring groove design, contribute to optimized cleanability. As a result, the seal is also suitable for sterile applications. A flushing system integrated in front of the dynamic sealing element on the product side is permanently supplied with nitrogen during operation. It also simplifies cleaning using the CIP process. This increases the operational reliability of the seal because it reliably removes product residues.

Dry nitrogen is used as barrier and flushing medium. As an inert gas, it is slow-reacting and therefore suitable for use in potentially explosive atmospheres. Large sealing surfaces in conjunction with an appropriate groove design ensure a high rigidity of the gas film and thus a reliable sealing function and low nitrogen consumption.

In addition to regular CIP cleaning via the flushing gas connection, the continuous application of buffer and flushing gas contributes to the extension of service life. This protects the seals even during standstill. As a further measure to increase the service life, regular buffer gas pressure surges were established during drying. Despite the demanding operating conditions, the gas-lubricated mechanical seals AGSR at Merck achieve a long service life of several years in practice.

AGS agitator seals – For maximum product purity. Designed for reactors, mixers, dryers and special machine.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.