EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

EagleBurgmann sets the standard for separation seals: CobaSeal enables a safe compressor shutdown at a venting pressure of up to 70 bar

Norms and standards make technology safe, environmentally sound and efficient. The US standard API STD 692 is used around the world for compressor operation. This standard recommends conducting vent studies to identify technical risks, environmental impact and efficiency under regular and extreme conditions. The robust, patented CobaSeal from EagleBurgmann sets the standard for separation seals, offering outstanding cost-efficiency and maximum safety.

Today’s centrifugal compressors typically feature two-stage, gas-lubricated mechanical seals combined with a separation seal. In most industrial applications, these compressors are process-critical components. This means high demands on availability, reliability and safety, making detailed specifications and in-depth expertise essential.

API STD 692 gives orientation

In 2018, the American Petroleum Institute published the standard API STD 692 for the operation of compressors. The guideline was developed by engineers, operators and manufacturers of compressors and sealing solutions and contains their combined expertise. Based on the tried and tested practices and recommended design criteria, API STD 692 offers information and recommendations for ensuring reliable, efficient and safe compressor operation.

Although gas-lubricated mechanical seals are the safest and most reliable seal technology for compressors, major seal failures have occurred in the past with serious consequences for people, the environment and associated technical systems. API STD 692 therefore expressly emphasizes the need to conduct comprehensive vent studies to investigate the operating behavior of the technical components up to the operating limits.

Vent studies for sealing systems

These vent studies involve technical examinations of worst case scenarios in order to identify safety-related weaknesses, evaluate risks and define appropriate measures. The measures may cover some or all components of a compressor such as the seal configuration, the separation seal design, the machine porting, or the seal supply system.

One dramatic scenario is the failure of the first and second seal of a gas-lubricated mechanical seal. This increases the pressure on the secondary vent, which can result in damage to the separation seal, leading to an unexpectedly large quantity of process gas penetrating into the shaft bearing. As the process gas flows through, particles from the damaged primary and/or secondary seal can be carried into the bearing chamber.

Other worst-case scenarios go even further by considering the possibility of vent restriction or blocking.

Separation seals are safety critical

Typical, non-coaxial separation seals consume large amounts of process gas even under normal operating conditions. In the described scenario, extreme quantities penetrate into the shaft bearing, significantly increasing the risk of a major incident.

The engineers at EagleBurgmann have now put their patented separation seal CobaSeal to the test. This robust seal demonstrates mechanical integrity up to 70 bar. The CobaSeal therefore allows a safe compressor shutdown even in emergencies.

More information can be requested by emailing info@eagleburgmann.com

CobaSeal info box

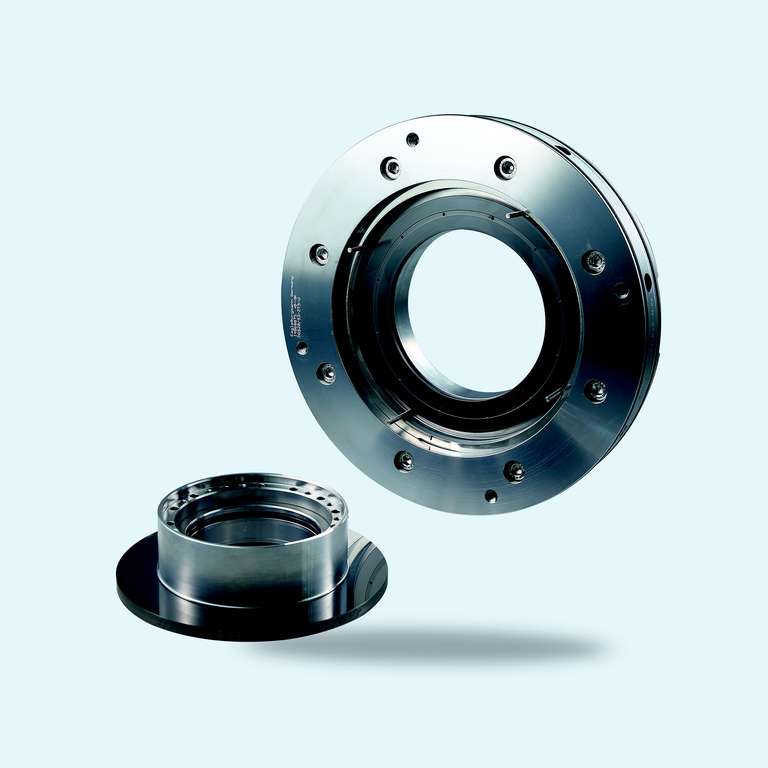

Since its introduction in 2008, the coaxial, gas-lubricated separation seal CobaSeal has proven itself around the globe in both first fit and retrofit applications. It consists of a rotating seat made of ductile material and a stationary, spring-loaded seal face. The separation gas is routed through axial holes in the stationary seal ring into the middle of the sliding face. It is then divided in the sealing gap into two leakage flows which are routed to the inner and outer diameters of the seal face.

Extremely low leakage is an essential feature of the CobaSeal. Compared to separation seals such as labyrinths or seals with carbon rings, the values of the CobaSeal are down by as much as 95 %.

The patented CobaSeal is also used as a true backup seal for greater safety in combination with a gas-lubricated single, double or tandem seal.