EagleBurgmann international

UK

UK

UK

UK

UK

UK

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Products

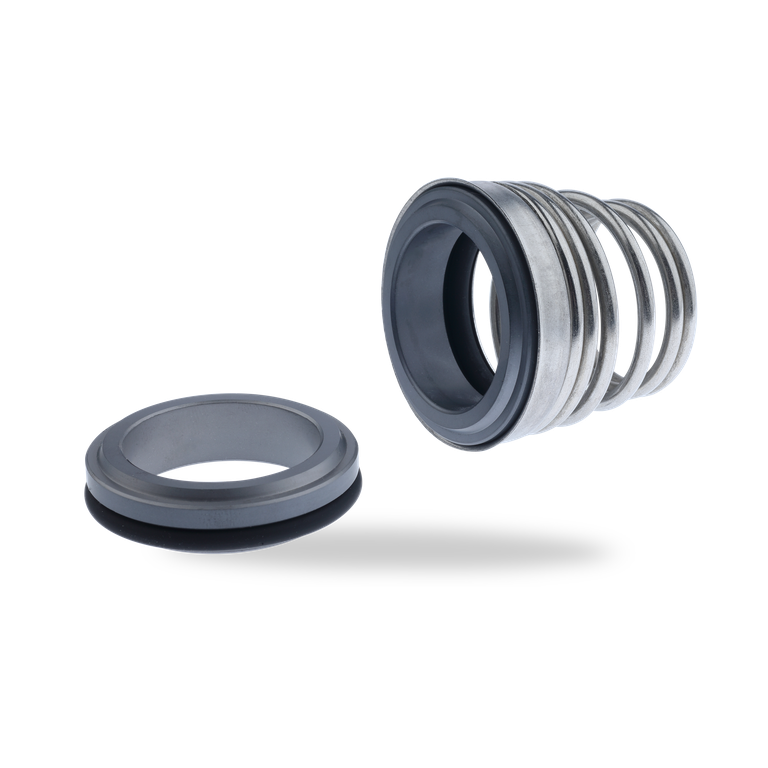

BT-FH

BT-FH

Features

- Single pusher-type seal

- Unbalanced

- Conical spring

- Dependent on direction of rotation

Advantages

The BT-FH is a seal for demanding applications where operating conditions in the pump require machined metal parts for the mechanical seal. The seals are available in a full range of diameters from 10 to 100 mm and in the standard diameters specifically for chemical applications.

Operating range

Shaft diameter:

d1 = 10 … 100 mm (0.39" … 3.94")

Pressure: p1*= 12 (16) bar (174 (232) PSI)

Temperature:

t* = -35 °C … +200 °C (-31 °F … +392 °F)

Sliding velocity: vg = 15 m/s (49 ft/s)

* Dependent on medium, size and material

d1 = 10 … 100 mm (0.39" … 3.94")

Pressure: p1*= 12 (16) bar (174 (232) PSI)

Temperature:

t* = -35 °C … +200 °C (-31 °F … +392 °F)

Sliding velocity: vg = 15 m/s (49 ft/s)

* Dependent on medium, size and material

Materials

Seal face:

Aluminium oxide (V), Silicon carbide (Q1), Tungsten carbide (U1)

Seat:

Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1), Tungsten carbide (U1)

Elastomers:

NBR (P), EPDM (E), FKM (V), FFKM (K)

Metal parts: CrNiMo steel 1.4401 (G)

Aluminium oxide (V), Silicon carbide (Q1), Tungsten carbide (U1)

Seat:

Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1), Tungsten carbide (U1)

Elastomers:

NBR (P), EPDM (E), FKM (V), FFKM (K)

Metal parts: CrNiMo steel 1.4401 (G)

Standards and approvals

- KTW

- W270

- ACS

- WRAS

- NSF

- FDA

- DM 174/04

Recommended applications

- Chemical industry

- Building services industry

- Centrifugal pumps

- Clean water pumps

Notes

Seat ring of alternative seats can be supplied with short tail or with pin to block the seat and prevent seat rotation.

Similar products

BT-FN

- Single seal

- For plain shafts

- Unbalanced

- Conical spring rotating

- Dependent on direction of rotation

- Torque transmission via conical spring

BT-FN

- Single seal

- For plain shafts

- Unbalanced

- Conical spring rotating

- Dependent on direction of rotation

- Torque transmission via conical spring

LY9TCS-F

- API 682 Category 2 and 3, Type C seal

- Dual seal, face-to-face

- Balanced

- Cartridge unit

- Stationary metal bellows

- Shrink fitted seal rings and solid mating rings

Contact

Inquire about individual solutions

We develop and produce customer-specific special and individual solutions for every application.