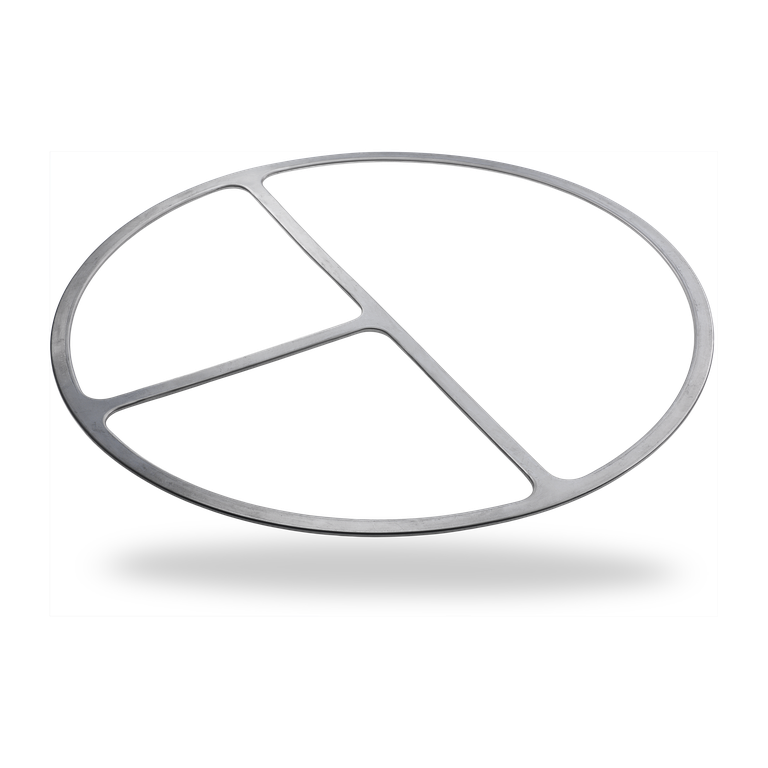

KN Rubber-PVC gasket 9117/KN

KN Rubber-PVC gasket 9117/KN

KN Rubber-PVC gasket 9117/KN

Features

The KN rubber-PVC gasket 9117/KN consists of a PVC support ring and a specially-molded, replaceable elastomer ring which is located in the force shunt after fitting.

Advantages

- The elastomer ring can be reused after replacement

- Reduced weight

- Easy handling, even with large diameters

- Segmented construction for optimized transport

- Segments may be assembled on site

Materials

- Sealing lip: EPDM (Shore-A-hardness 70 ± 5)

- Outer ring: PVC

Recommended applications

Industries

- Power plant technology

- Water and waste water technology

- Building services engineering

- Flange connections

- Pipe connections

Functional description

The EPDM sealing lip is fitted on the inner diameter of the PVC ring. The PVC ring acts as both a supporting and a centering ring. It also absorbs the bolt force which is needed particularly when there are high pressures to be sealed, and thus protects the elastomer ring against excessive compression. The PVC ring does not come into contact with the medium.

Notes

Production note:

Up to DN 800 or 32”, the sealing lip is produced by injection molding. This is superior to frequently used displacement method with open molds as it offers greater dimensional accuracy. Above DN 800 or 32”, the sealing lip is extruded and is sold by length with instant adhesive for on-site assembly.

Up to DN 800 or 32”, the sealing lip is produced by injection molding. This is superior to frequently used displacement method with open molds as it offers greater dimensional accuracy. Above DN 800 or 32”, the sealing lip is extruded and is sold by length with instant adhesive for on-site assembly.

Forms of supply

- Up to DN 600 (24”), the gasket is produced as a single piece.

- Above DN 600 (24”), the seal is produced in easy to transport segments and then assembled.

- Standard dimensions as defined in the EagleBurgmann in-house standard for DIN flanges or for flanges to ANSI B16.5 and MSS SP-4.4

Similar products

Buralloy Heat exchanger seal 2500

The Buralloy heat exchanger seal 2500 is a semi-metal gasket with a soft core and metal jacketing. The Buralloy 2500 thus combines the benefits of a compressible soft seal with the mechanical strength of a metal seal. As a result, it can be produced in many different material combinations and in different styles to suit the application.

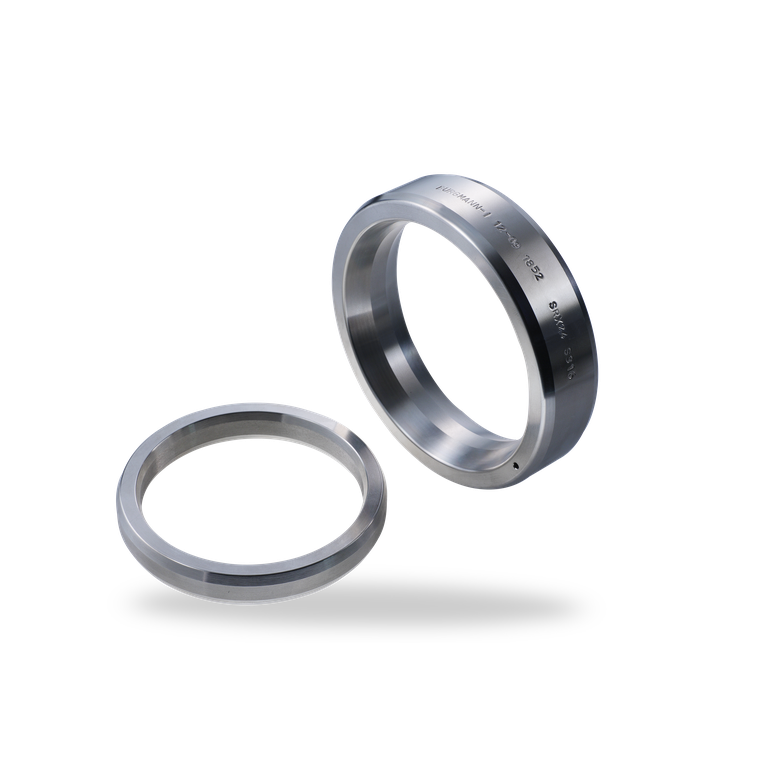

Buralloy Ring Type Joint 2961

Buralloy ring-type joint 2961 (RTJ) gaskets are manufactured from metallic materials in compliance with American standard ASME B 16.20 and the API specification. Detailed monitoring of every manufacturing step guarantees that the sealing rings offer the necessary surface hardness. This creates a functional seal without damage to the flanges. This gasket type is used successfully in downstream refinery applications, for example. RTJ gaskets are also commonly used in high-pressure valves and the associated pipe connections and in pressure vessel joints.

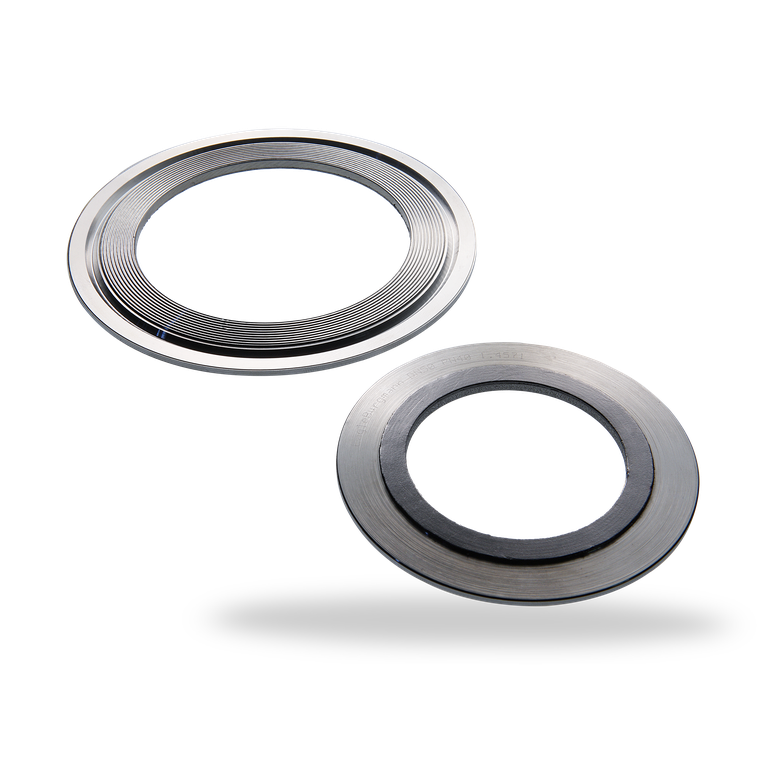

Camprofile serrated gasket 9588

The serrated gasket 9588 has a concentrically-machined profile based on a 4 mm thick stainless steel base plate. This is coated on both sides with a 0.5 mm thick layer of pure graphite (purity > 98%). Thicker layers are available on request. The serrated gasket 9588 is easy to handle and is particularly suitable for applications in the chemical and petrochemical industries and in power station technology.